Reliability Dynamics Partners with CCPS PERD to Deliver New Equipment Reliability Data Toolset

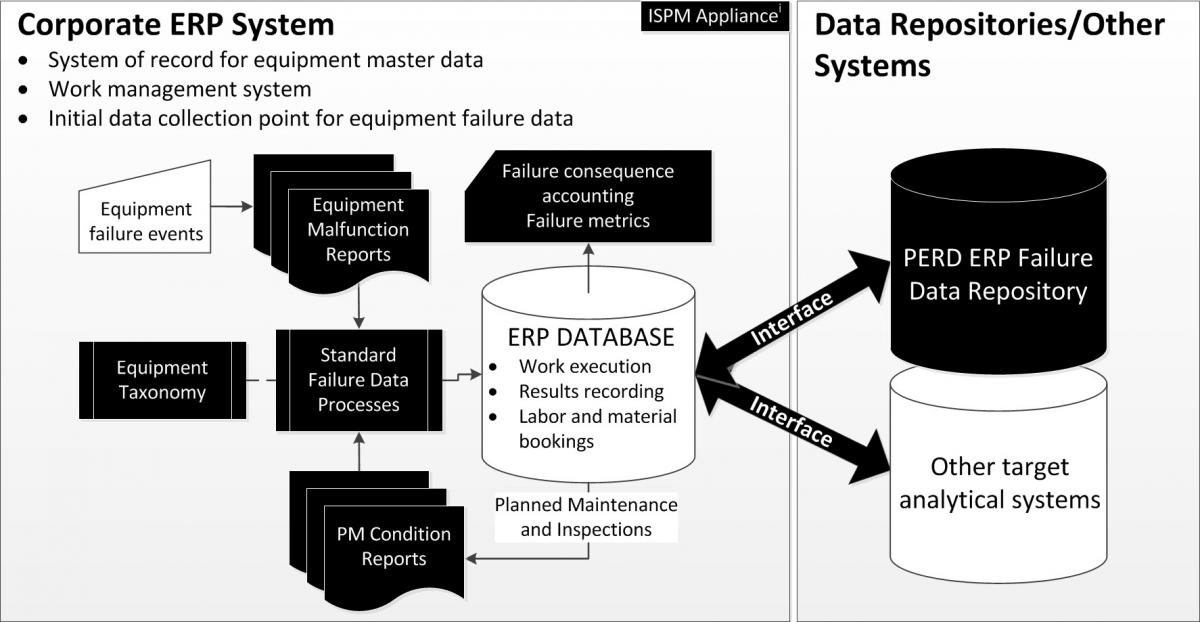

Reliability Dynamics is working in collaboration with the Center for Chemical Process Safety (CCPS) Process Equipment Reliability Database (PERD) Subcommittee to improve quality and availability of equipment failure data for chemical and hydrocarbon processing industries. Objectives of the initiative, called PERD ERP, are (1) to improve equipment failure data at the source by giving individual CPI/HPI companies guidance and standard methods for using ERP software to collect high-quality failure data, and (2) to simplify and improve data exchange by using common enterprise resource planning (ERP) software for the PERD data repository. Collaborators from industry are needed to give input on and participate in further development of standard methods for asset management with ERP systems (possibly a new CCPS guidelines publication) and for implementation and usage of the new methods.

Poor equipment reliability data quality in ERP systems is a prevalent issue in CPI/HPI companies. It affects local decision-making for equipment assets and results in poor data quality transferred to any failure data tool or repository, e.g. PERD, OREDA, Meridium, etc.). PERD ERP addresses ERP data quality issues with detailed engineering-based guidance and standard methods for reliability data collection and aggregation in ERP systems, e.g. standard coding processes, standard schema, minimum data specifications, and data validations. Additionally, PERD ERP eliminates the need for a local stand-alone PERD application, as individual corporate ERP systems now serve that purpose. Reliability data from corporate ERP systems are easily complied in the PERD ERP central instance (database), given the use of like software.

PERD ERP member companies will benefit in two ways, (1) from improved in-house failure data methods and high-quality structured data, and (2) from better industry aggregate data. High-quality structured data mean better (data –driven) decisions for equipment assets, which in turn lead to improved profitability, safety, and compliance

PERD ERP methods are compliant with international standard ISO 14224 and consistent with CCPS guidelines and international standard ISO 15926-2. Thus PERD ERP will help companies demonstrate their asset management practices are consistent with good engineering practice.

The Center for Chemical Process Safety has been providing quantitative risk assessment data to the chemical process industries since the 1980s, and published the first of its “CCPS Guidelines for Process Equipment Reliability Data” in 1989. Subsequent enhancements to this information-collection effort led to PERD, which has provided deeper and more specific analyses of equipment availability, reliability, design improvements, maintenance strategies, and life cycle cost determination.

For more information about PERD ERP or to get involved, please contact Tony Ciliberti, PE, at Reliability Dynamics, or Dave Belonger at CCPS (perd@aiche.org).

PERD ERP solution overview